涡轮监控仪器(TSI)#1

问题:

美国西部的一家电力公司面临着需要更换现有但已过时的涡轮机监控仪表(TSI)的麻烦。现有系统具有所有常见的涡轮机监控参数,包括10个轴承上的X / Y径向振动,2个推力位置,速度,零速/加速比,偏心率,HP和LP壳体膨胀,差动膨胀,2个阀位和关键相位。

客户还需要带有径向继电器,推力位置和系统正常的可调继电器的“硬警报”。每个系统通道都有独立可调的继电器闭锁装置,用于警报和危险,以及一个单独的继电器,用于系统正常运行。该客户希望将继电器绑在一起,因此每个参数只有一个接线盒;警报,危险和系统正常。仅需要其余的TSI功能显示,因此未提供硬警报/继电器。

此外,客户还对本地显示振动,速度,阀位置和偏心率有要求。除本地显示外,还有一条数字Modbus TCP / IP通信链接到Plant Data Historian,以长期趋势显示所有监视的参数。

现有系统安装在涡轮发电机组附近的本地仪表板上。客户希望利用现有的传感器接线,并希望利用现有的面板开口直接替换该系统。此外,客户希望系统完整到可以简单地安装面板,提供系统电源并将传感器连接到中间接线盒的程度。

为了协助进行改造,该公用事业公司选择了Fastrack Technologies LLC,这是位于普莱森顿的STI代表。 Fastrack Technologies和STI共同创建了一个满足其所有需求的经济有效的解决方案。

解决方案:

Fastrack Technologies总工程师David Poffenbarger参观了客户的现场,以开发可行的解决方案。 Fastrack Technologies与STI共同设计了一个系统,以最大程度地减少移除旧的过时系统的影响,从而创建了真正的“螺栓连接”解决方案,该解决方案仅需几天就可以更换。

STI制造了定制的“ Mimic”和“ Monitoring”面板,它们利用本地仪器柜中的现有孔直接替代了旧的过时系统。提供了定制的接线器,以将两(2)个面板连接在一起。此外,STI还提供了CMCP500系列监测器和变送器,用于推力,振动,偏心率,关键相量和微分膨胀的近程探头系统以及用于壳体膨胀和阀位置的CMCP-LVDT-AC LVDT。

一旦系统制造完成并交付给客户,就可以在短暂的设备停机期间安装系统。 Fastrack Technologies在安装和最终校准/设置TSI功能期间提供了工程支持。

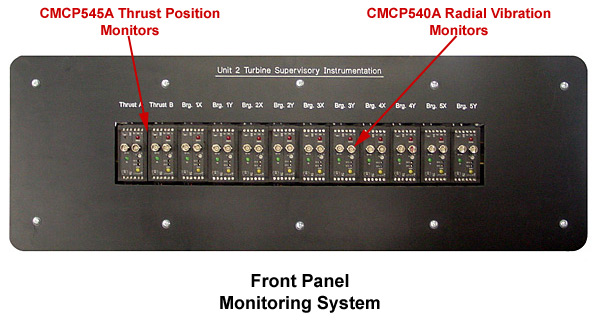

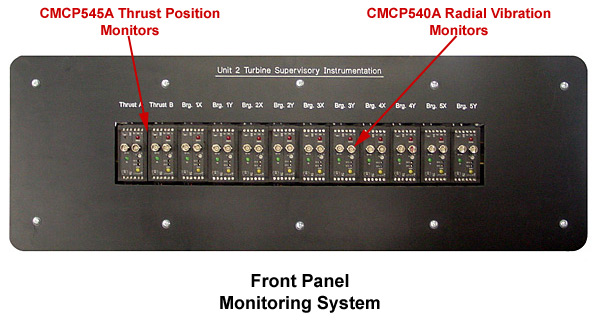

A.监控面板:

“监视面板”包括两(2)个CMCP545A推力位置监视器和十(10)个CMCP540A径向振动监视器。

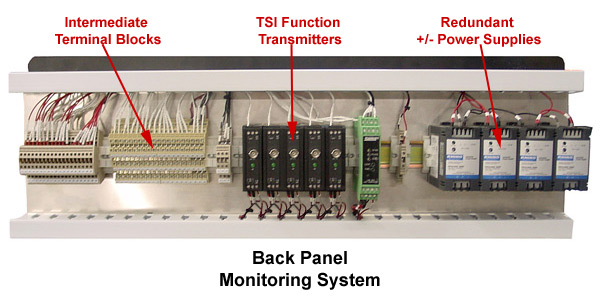

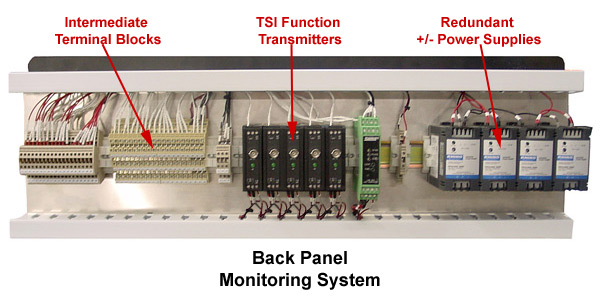

“监控面板”的背面包括冗余+/- 24 VDC电源,所有TSI功能变送器和中间端子块。线材导引装置提供了整洁有序的外观。

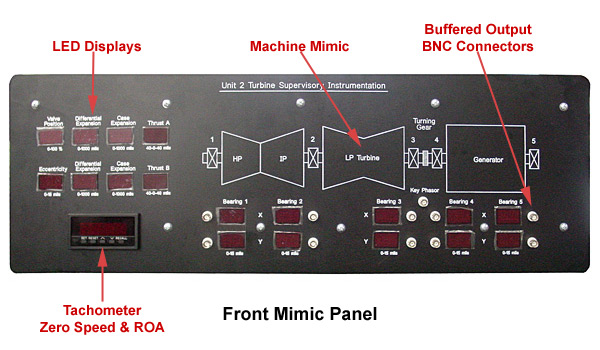

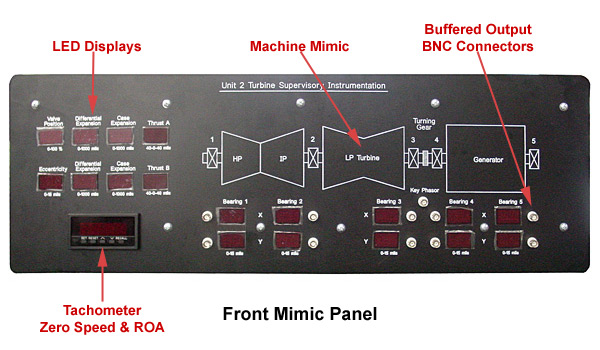

B.模拟面板:

“模拟面板”包括所有推力,振动和TSI功能值的亮红色LED显示,用于访问传感器缓冲动态输出的BNC连接器,机器“模拟”和用于速度,加速度和零速度的CMCP-Tach3 。

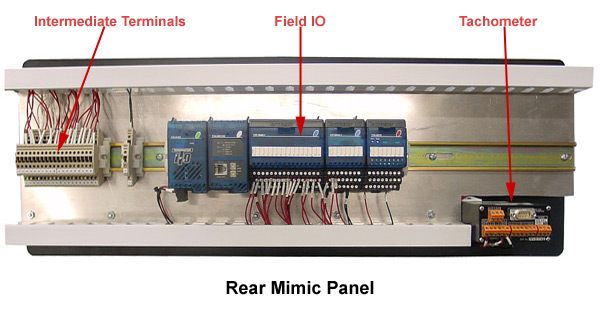

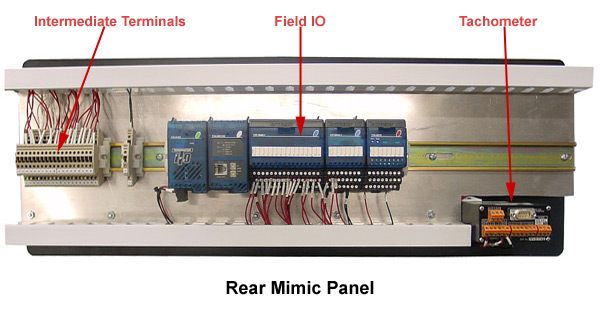

“模拟面板”的背面包括中间接线盒和Modbus TCP / IP Field IO。 IP地址是在装运前由STI分配的。线材导引装置提供了整洁有序的外观。

整个系统是模块化的,可以根据需要更换每个组件,从而使客户人员的维护和故障排除变得简单明了。为客户完成了完整的接线图包,并将其包含在订单中。

如果您对TSI Systems有任何疑问或意见,请与我们联系。我们在这里回答您的问题。

Turbine Supervisory Instrumentation (TSI) #1

The Problem:

A Western U.S. power company was faced with needing to replace an existing, but obsolete, Turbine Supervisory Instrumentation (TSI). The existing system had all the common turbine monitoring parameters including X/Y Radial Vibration on 10 Bearings, 2 Thrust Position, Speed, Zero Speed/Rate of Acceleration, Eccentricity, HP & LP Case Expansion, Differential expansion, 2 Valve Position and KeyPhasor.

The customer also required “Hard Alarms” with adjustable relays for Radial Vibration, Thrust Position and System OK. Each system channel has independently adjustable relay closures for Alert and Danger, and a separate relay for system OK. This customer wanted relays tied together so there was only 1 terminal block for each parameter; Alert, Danger and System OK. The remaining TSI functions only required Displays so hard alarms/relays were not provided.

Additionally, the customer also had requirements for local display of vibration, speed, valve position and eccentricity. In addition to the local displays, a Digital Modbus TCP/IP communications link to the Plant Data Historian for long term trending of all monitored parameters.

The existing system was mounted in a local instrument panel adjacent to the Turbine Generator Set. The customer wanted to make use of existing sensor wiring and have the system to be a direct “bolt in” replacement utilizing the existing panel openings. Additionally, the customer wanted the system complete to the point they could simply mount panels, provide system power and connect sensors to the intermediate terminal blocks.

To assist with the retrofit, the utility selected Fastrack Technologies LLC, a STI Representative based in Pleasanton. Fastrack Technologies and STI worked together to create a cost effective solution that met all their needs.

The Solution:

Fastrack Technologies principal engineer David Poffenbarger visited the customer’s site to develop a workable solution. Fastrack Technologies, working together with STI, engineered a system to minimize impact of removing the old obsolete system, creating a truly “bolt in” solution that could be changed out in only a couple days.

STI manufactured custom “Mimic” and “Monitoring” Panels that directly replaced the old obsolete system, utilizing the existing holes left in the local instrument cabinet. Custom wiring looms were provided to connect the two (2) panels together. Additionally, STI provided CMCP500 Series Monitors and Transmitters, Proximity Probe Systems for Thrust, Vibration, Eccentricity, Keyphasor and Differential Expansion and CMCP-LVDT-AC LVDT’s for Case Expansion and Valve Position.

Once the system was manufactured and shipped to the customer, the system was installed during a short unit outage. Fastrack Technologies provided engineering support during the installation and final calibration/setup TSI functions.

A. Monitoring Panel:

The “Monitoring Panel” included two (2) CMCP545A Thrust Position Monitors and ten (10) CMCP540A Radial Vibration Monitors.

The rear of the “Monitoring Panel” included Redundant +/- 24 VDC Power Supplies, all TSI Function Transmitters and Intermediate Terminal Blocks. Wire guide was provided for a neat and orderly appearance.

B. Mimic Panel:

The “Mimic Panel” included Bright Red LED Displays of all Thrust, Vibration and TSI Function values, BNC connectors for access to the sensor buffered dynamic output, a machine “Mimic” and a CMCP-Tach3 for Speed, Rate of Acceleration and Zero Speed.

The rear of the “Mimic Panel” included Intermediate Terminal Blocks and Modbus TCP/IP Field IO. IP address was assigned by STI prior to shipment. Wire guide was provided for a neat and orderly appearance.

The entire system is modular and each component can be replaced as needed making maintenance and troubleshooting by customer’s personnel straightforward. A complete wiring drawing package was completed for the customer and included in the order.

If you should have any questions or comments about TSI Systems please contact us. We are here to answer your questions.